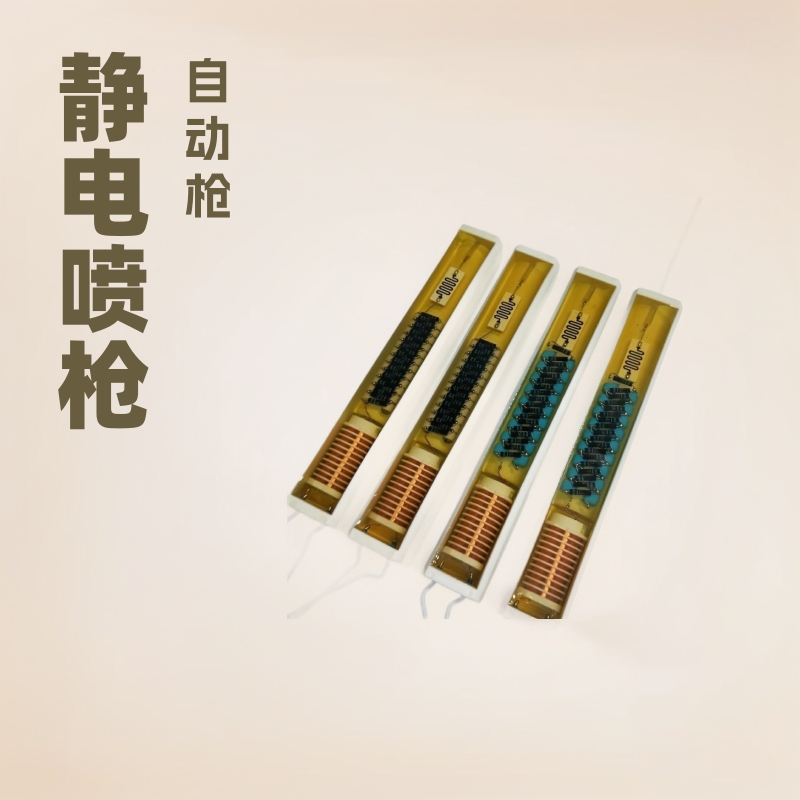

Jinma third-generation electrostatic spray gun manual and automatic gun voltage cultivation module

Upgrade Your Coating Process with the 4.0 Gold Horse Fourth-Generation Lab Electrostatic Sprayer

Are you searching for a versatile, efficient, and high-performance coating solution for small-batch processing? Look no further than the 4.0 Gold Horse Fourth-Generation Laboratory Electrostatic Spraying Machine. Designed for precision and flexibility, this machine is the ideal partner for R&D, prototyping, and small-scale production.

A standout feature of this model is its rapid color change capability, specifically engineered for small-batch operations. This drastically reduces downtime between jobs, increases throughput, and minimizes material waste. It's the perfect solution for applications requiring frequent color switches or testing various finishes.

Built to the high standards of the Chuheng brand, this machine is not an import but offers exceptional domestic quality and reliability. Key specifications include a maximum output pressure of 0.8 MPa, an air consumption of 0.4 MPa, and a power rating of 50. Its air-powered, airless electrostatic design ensures a fine, uniform finish with excellent material transfer efficiency.

The sprayer comes equipped with the enhanced Gold Horse Third Generation Extended Conductive Needle (Ordering Number). This extended rod design improves electrostatic field stability and wrap-around capability, ensuring even coverage on complex part geometries. With a recommended spraying distance of 15-20 cm and an adjustable spray width up to 25 cm, it offers great control for detailed work.

Versatility is guaranteed with multiple nozzle diameter specifications available for selection, allowing you to tailor the machine to different material viscosities and coating requirements. Whether for surface treatment in manufacturing, model finishing, or educational purposes, this electrostatic sprayer delivers professional results.

Invest in the 4.0 Gold Horse Fourth-Generation Lab Electrostatic Sprayer for a smarter, faster, and more economical coating process. Its combination of rapid color change, electrostatic efficiency, and robust construction makes it an invaluable asset for any lab or small workshop aiming for excellence in surface finishing.